|

Free

Standing Work Station

Bridge Cranes

|

|

|

|

|

|

| |

| |

|

|

|

|

|

The safe, productive,

ergonomic solution for

overhead materials handling operations.

|

|

Enclosed

Track Design Makes for Easy

Movement and Long Life |

|

|

|

|

|

|

|

|

|

|

The steel Work

Station Crane System utilize enclosed

track that is high in strength and low in weight. Major

advantages:

• Enclosed track cranes are up to three times easier to

move than traditional bridge cranes.

• The design virtually eliminates dirt and dust from the

rolling surface, thus reducing wear on the wheels of

the trolley and end trucks.

• The smooth running surface means lower rolling

resistance.

• The low profile of the steel track allows the system

to be installed where headroom is a problem.

• The low track weight reduces the applied forces

exerted on the supporting structure.

• Long spans allow systems to be installed where

support assemblies are infrequent (up to 30 feet with

steel truss design). This reduces the possibility of the

support columns interfering with the work cell layout.

• Four distinct sizes of track -- 250, 500, 1000, and

2000 series -- enable you to keep bridge weights

and costs to a minimum. |

|

|

|

|

|

Pricing

and Dimensional Specifications -

Click a Load Capacity Link Here |

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Rigid

Runways Provide for Superior

Positioning of Loads |

|

|

|

|

|

|

|

|

|

|

|

|

The

2° taper of the running

flange helps to center the

trolley in the track for smooth,

effortless movement of trolleys

and end trucks. |

|

|

Work Station Bridge Cranes

are installed so that the

runways are rigid. They do not move laterally or

longitudinally. In addition, the floating end trucks with

horizontal wheels prevent binding. The combination of

these design features results in unmatched ease of

positioning and ease of movement. The bridge travels

smoothly down the runways, and movement is unvarying

along the way, no matter where a load is positioned on

the bridge. This allows superior load positioning.

Another advantage of rigid runways is that runways

double as stringers between support columns. This

eliminates the need for expensive intermediate support

stringers, and it lowers overall installation cost.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| What

is meant by Rated Capacity? |

|

|

|

|

|

|

|

|

|

|

|

|

|

The

rated capacity is the live load that can be lifted by

the crane system. The design load for the crane system

is based on the rated capacity plus 15% for the weight

of the hoist and trolley (capacity x 1.15) and an additional

25% for impact (capacity x 1.25) for a total design of

capacity x 1.4 (Note, 25% impact factor is good for

hoist speeds up to 50 f.p.m.). For example, a 1000 lb.

crane allows you to pick up a 1000 lbs. load, provided

the hoist weights 150 lbs. or less and the hoist speed is

less than 50 feet per minute. |

TRUSSED

STEEL TRACK: |

|

|

|

|

|

|

|

|

Permits

longer spans which allows more flexibility

in crane layout. |

|

|

|

|

|

|

|

|

|

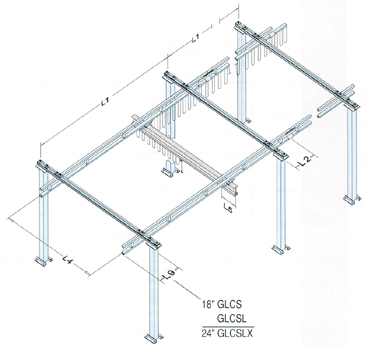

The trussed series uses the

plain steel track profile but is

enhanced for longer spans via a built-up truss design. This

design increases the span, which decreases the need for

frequent hangers. Model numbers start with: GLCS-FS

for spans up to 20 feet, GLCSL-FS for spans up to 25

feet, and GLCSLX-FS for spans up to 30 feet.

Long spans translate into fewer runway support points,

less interference of work cell layout, longer bridge lengths,

and free standing capabilities... just another reason why

these Work Station Cranes are among the most versatile

to apply and easiest to install in the industry.

|

|

|

|

|

Design

load for deflection calculations is based on

the rated capacity plus 15% for the weight of the hoist

and trolley (capacity x 1.15). Under no conditions should

the crane be loaded beyond it rated capacity. Work

Station Cranes meet or exceed the ANSI B30.11

specifications for underhung bridge cranes. |

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Mixed

Capacity Bridge Crane Systems: |

|

Easy

to Install |

|

|

|

|

Reduced

bridge dead weight equals better ergonomic

solutions. |

|

Free

Standing Work Station Bridge Cranes can be

installed on any normal 6" reinforced concrete floor.

Each column is anchored by four bolts, thus eliminating

the need for field welding.

Support columns are designed to AISC specifications. If

no movement of the support assemblies is required, then

bracing to the building is recommended (not included). |

|

|

Mixed-capacity

systems allow multiple lower capacity

bridges to be used on higher capacity runways, provided

the equivalent center loads (ECL) are verified at the

factory to ensure that runways and hangers are not

overloaded. For example, using mixed-capacity end

trucks, four 500 lb. bridges (utilizing 500 series rail)

can be hung from a 2000 lb. runway, allowing side-by-

side use of all four bridges without overloading the

system. By mixing bridges of various sizes and cap-

acities, mixed-capacity systems offer reduced bridge

dead weight, easier movement, and reduced cost. |

|

|

|

|

|

Modular

Design |

|

The

pre-engineered modular kit design permits easy

expansion or relocation. The runway length can be

increased by adding runway sections, free standing

support assemblies and additional bridges as needed. |

|

|

|

|

Pricing

and Dimensional Specifications -

Click a Load Capacity Link Here > |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

CAPACITY |

SERIES |

WEIGHT

PER

FOOT |

MAX.

L1 |

MAX.

L2 |

MAX.

L5 |

MAX.

L9 |

| 250# |

GLCS |

4.88# |

20' |

48" |

18’’ |

48’’ |

|

GLCSL |

8.14# |

25' |

48" |

18’’ |

48’’ |

| 500# |

GLCS |

7.23# |

20' |

48" |

18’’ |

48’’ |

|

GLCSL |

10.94# |

25' |

48" |

24’’ |

48’’ |

|

GLCSLX |

11.26# |

30' |

48" |

24’’ |

48’’ |

| 1000# |

GLCS |

12.09# |

20' |

48" |

24’’ |

48’’ |

|

GLCSL |

13.37# |

25' |

48" |

24’’ |

48’’ |

|

GLCSLX |

15.31# |

30' |

48" |

24’’ |

48’’ |

| 2000# |

GLCS |

14.59# |

20' |

48" |

24’’ |

48’’ |

|

GLCSL |

20.14# |

25' |

48" |

24’’ |

48’’ |

|

GLCSLX |

20.95# |

30' |

48" |

24’’ |

48’’ |

| 4000# |

GLCS |

18.42# |

20' |

48" |

24’’ |

48’’ |

|

GLCSL |

23.83# |

25' |

48" |

24’’ |

48’’ |

|

GLCSLX |

28.02# |

30' |

48" |

24’’ |

48’’ |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

L

1 = |

MAXIMUM

SUPPORT ASSEMBLY CENTERLINE

Maximum Support Assembly Centerline is con-

sidered from the center of a support assembly to

the center of the neighboring support assembly. |

|

|

|

|

|

|

| Note: |

Anti-kick-up

end trucks* are required for the following:

bridges with < 8' span (L4) and a bridge

cantilever (L5) > 12"

bridges with < 10' span (L4) and a bridge

cantilever (L5) > 15"

bridges with < 15' span (L4) and a bridge

cantilever (L5) > 18" |

|

|

|

|

|

|

|

L

2 = |

SPLICE

JOINT CENTERLINE TO SUP-

PORT ASSEMBLY CENTERLINE

Splice Joint Centerline to Support Assembly Cen-

terline is considered from center of a splice joint

to the center of the nearest support assembly. |

|

|

|

|

|

**

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

L

4 = |

BRIDGE SPAN

Bridge Span is considered from centerline to cen-

terline of runways.

L4 = Bridge Overall Length - (2 x Bridge Centerline)

|

|

|

|

|

|

|

|

|

|

|

*

Anti-kick-up end trucks are not included as part

of the standard crane kits.

**2000# @ 10' span (L4) and bridge cantilever (L5)

15" need anti-kick-up end trucks.

Consult us for information on bridges greater

than 15' span (L4). |

|

|

|

|

|

| L

5 = |

BRIDGE

CANTILEVER

Bridge Cantilever is considered from the center-

line of the runway to the end of the bridge (see

table and notes). |

|

|

|

|

|

|

|

|

|

STANDARD BRIDGE CANTILEVER

|

Bridge

Series |

Bridge Overall Length |

|

Steel |

|

<=23' |

28' |

29' |

33' |

34' |

| 250# |

12" |

18" |

24" |

NA |

NA |

| 500# |

12" |

18" |

24" |

18" |

24" |

| 1000# |

12" |

18" |

24" |

18" |

24" |

| 2000# |

12" |

18" |

24" |

18" |

24" |

| 4000# |

15" |

18" |

24" |

18" |

24" |

|

|

|

|

|

|

L

9 = |

MAXIMUM

RUNWAY CANTILEVER

Runway Cantilever is considered from the center

of the end support assembly to the end of the

runway. |

|

|

|

|

|

|

|