|

|

|

|

|

|

|

|

|

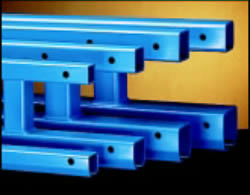

Rigid

Runways Provide for Superior

Positioning of Loads |

|

|

|

|

|

|

|

|

|

|

|

|

The

2° taper of the running

flange helps to center the

trolley in the track for smooth,

effortless movement of trolleys

and end trucks. |

|

|

Work Station Bridge Cranes

are installed so that the

runways are rigid. They do not move laterally or

longitudinally. In addition, the floating end trucks with

horizontal wheels prevent binding. The combination of

these design features results in unmatched ease of

positioning and ease of movement. The bridge travels

smoothly down the runways, and movement is unvarying

along the way, no matter where a load is positioned on

the bridge. This allows superior load positioning.

Another advantage of rigid runways is that runways

double as stringers between support columns. This

eliminates the need for expensive intermediate support

stringers, and it lowers overall installation cost.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| What

is meant by Rated Capacity? |

|

|

|

|

|

|

|

|

|

|

|

|

|

The

rated capacity is the live load that can be lifted by

the crane system. The design load for the crane system

is based on the rated capacity plus 15% for the weight

of the hoist and trolley (capacity x 1.15) and an additional

25% for impact (capacity x 1.25) for a total design of

capacity x 1.4 (Note, 25% impact factor is good for

hoist speeds up to 50 f.p.m.). For example, a 1000 lb.

crane allows you to pick up a 1000 lbs. load, provided

the hoist weights 150 lbs. or less and the hoist speed is

less than 50 feet per minute. |

TRUSSED

STEEL TRACK: |

|

|

|

|

|

|

|

|

Permits

longer spans which allows more flexibility

in crane layout. |

|

|

|

|

|

|

|

|

|

The trussed series uses the

plain steel track profile but is

enhanced for longer spans via a built-up truss design. This

design increases the span, which decreases the need for

frequent hangers. Model numbers start with: GLCS-FS

for spans up to 20 feet, GLCSL-FS for spans up to 25

feet, and GLCSLX-FS for spans up to 30 feet.

Long spans translate into fewer runway support points,

less interference of work cell layout, longer bridge lengths,

and free standing capabilities... just another reason why

these Work Station Cranes are among the most versatile

to apply and easiest to install in the industry.

|

|

|

|

|

Design

load for deflection calculations is based on

the rated capacity plus 15% for the weight of the hoist

and trolley (capacity x 1.15). Under no conditions should

the crane be loaded beyond it rated capacity. Work

Station Cranes meet or exceed the ANSI B30.11

specifications for underhung bridge cranes. |

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|