|

HOW TO

ORDER PALLET RACKS

|

|

| Step

1 |

|

|

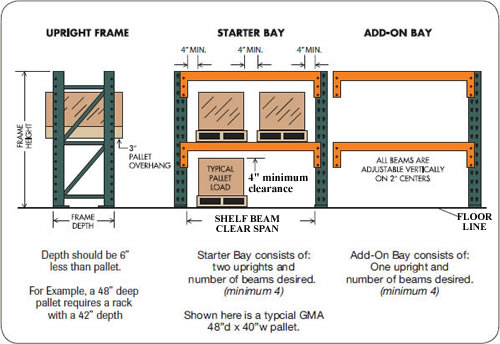

Select

Upright Frames

Add the following figures:

Height of pallet loads (including pallet)

+ Height of shelf beam

+ 4" Min. vertical clearance for each

pallet load

Sum of above dimensions = rack

height |

|

|

|

For

uppermost load level, location of shelf

beam should be 6" less than fork truck’s

maximum lift height. Top of beams need

to be at even increments. |

|

|

|

| Step

2 |

|

|

|

| Select

Beams |

|

Shelf

length equals the distance

between uprights. It is determined by

adding the widths of pallet loads plus

a 4" side clearance between upright

and pallet and 4" between pallet loads. |

|

|

|

|

|

| Step

3 |

Step 4 |

|

|

|

|

|

| Select

Decking |

Select

Accessories |

|

|

|

Shelf

beam capacities are based on

a pair of beams supporting an evenly

distributed load. |

|

| Select

Decking based on style needed: |

|

|

|

•

Solid Panel Decking

• Wire Decking |

|

|

|

|

|

|

Beams

over 120" in length should be tied

together with the appropriate front-to-back

support to maintain proper spacing at each

storage level. |

|

|

|

|

|

|

|

|

|

Pallet

Rack - Upright Frames

|

|

|

|

|

|

|

| Upright

Ordering Information |

|

|

|

|

| •

Choose uprights to suit your storage requirements: |

|

|

|

|

» Medium-Duty

- 3" x 2-1/4", 14 gauge

» Heavy-Duty - 3" x 3", 13 gauge |

|

|

|

•

Two frames are required per bay, and any number may

be joined together in continuous row applications

• Available in Lake Green |

|

|

|

|

|

|

|

|

Uprights

conform to the latest standards set by

Rack Manufacturers’ Institute LRFD Specifications. |

|

|

|

|

|

|

|

|

Unique

Design - Roll formed upright provides greater strength-to-

weight ratio. Minimum-sized slots mean more steel per upright.

Upright's structures are 100% mig-welded with precision K-brace

and heavy-duty cross channel reinforcement for increased strength,

rigidity and resistance to abuse. |

|

|

|

|

|

|

|

|

|

|

|

Easy

Adjustment - Tapered keyhole slots on 2" centers, provide

quick, easy vertical adjustment of beams. There are no “dead spots”

or obstructions in upright posts to impede movement of beam along

the entire height. |

|

|

|

|

|

|

|

|

|

Interchangeable

- Our pallet rack fits with other traditional

teardrop designs. That means you can upgrade damaged, weak,

or worn out uprights and beams with our versatile rack. No need

to change your whole system. |

|

|

|

|

|

|

|

|

|

|

|

|

PALLET

RACK SAFETY RECOMMENDATIONS

|

|

|

|

|

Determine

actual load requirements as accurately as possible

and adhere to rated capacities shown in tables on the preceeding

pages. Additional precautions should be taken in applications

where extraordinary rack abuse is anticipated. For example,

when narrow aisles are used for high speed or high inventory turn-

over operations, We recommend additional rack reinforcement.

Impact supports and aisle guidance devices may be advisable –

especially at aisle intersections and other vulnerable locations. |

Beam

Length |

|

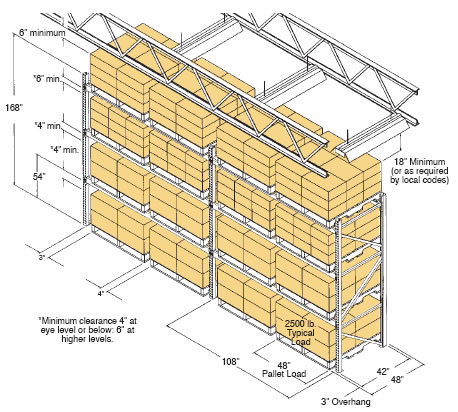

We

recommend a clearance of 4" between

palletized loads – and between loads and

uprights. Beams over 120" in length should

be tied together with the appropriate front-

to-back support to maintain proper spacing

at each storage level. |

|

|

|

| Back-to-back

Clearance |

|

|

|

|

Clearance

should be sufficient to

accommodate minimum pallet overhang

and tolerances – where pallet placement

may vary. Additional clearances may be

required to accommodate building

structures or intermediate sprinkler

systems (according to local codes). |

|

|

|

|

|

| Installation

and Anchoring |

|

To

insure minimum stability standards, racks

should be level, plumb and properly

anchored. |

|

|

|

| Seismic

Zones |

|

Since

requirements vary so widely, we

advise you to contact us for assistance on

rack projects in high risk seismic zones. |

|

|

|